Installing a new heater is a big investment, and following the right guidelines helps you get safe, efficient, long‑lasting performance. These key steps explain what homeowners should know and what to expect before, during, and after new heater installation.

1. Start with a proper home assessment

Before choosing equipment, your contractor should evaluate your home instead of just matching the size of your old unit. They will look at square footage, insulation levels, window quality, air leaks, and your local climate to calculate how much heating capacity you actually need.

A correct load calculation helps avoid oversizing, which can lead to short cycling, uneven temperatures, and higher energy bills, or undersizing, which leaves your home cold on the chilliest days. Ask your installer to explain their sizing method and confirm it follows industry standards rather than rule‑of‑thumb guesses.

2. Choose the right type and efficiency

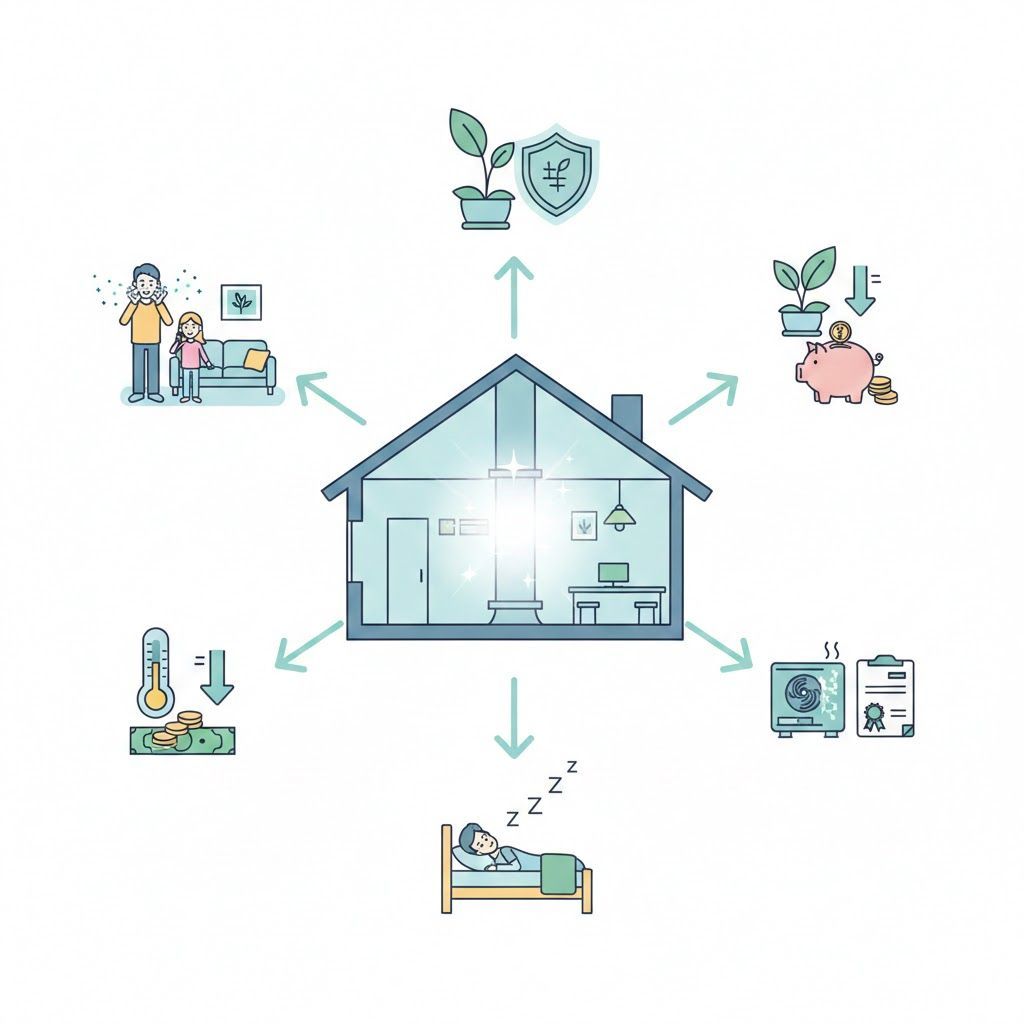

Once sizing is clear, you’ll decide between options like gas furnaces, electric furnaces, or heat pumps, depending on energy prices and how cold your winters get. Each system has different efficiency ratings—such as AFUE for furnaces or HSPF and SEER for heat pumps—that indicate how much of the energy you pay for becomes usable heat.

Higher‑efficiency models usually cost more upfront but can significantly cut monthly energy bills over the life of the system, especially if you run the heater often. Your contractor should walk you through projected operating costs and any available rebates so you can compare options based on total long‑term value, not just initial price.

3. Prepare the installation area

Before work starts, the installation area should be clear, safe, and up to code so the new heater can be installed correctly. This typically includes removing clutter, ensuring there is enough clearance around the unit for airflow and service access, and confirming that the floor or platform is stable and level.

For gas or oil systems, proper ventilation and combustion air are critical to prevent carbon monoxide buildup and other safety risks. Electrical panels, wiring, and dedicated circuits may also need to be checked or upgraded so the new heater has the correct power supply and grounding.

4. Safe removal of the old heater

When replacing an existing system, the old heater must be carefully disconnected and removed without damaging ducts, wiring, or gas lines. Technicians will shut off power and fuel, disconnect venting and duct connections, and then haul out the old unit for proper disposal or recycling according to local regulations.

This step is also a good time to inspect and clean the surrounding area, seal any gaps, and check for issues like rusted flue pipes, damaged drain lines, or deteriorated platforms that need repair before the new heater goes in. Addressing these issues now helps avoid leaks, performance problems, or safety hazards later.

5. Correct placement, connections, and venting

During installation, the new heater must be positioned, leveled, and secured according to the manufacturer’s instructions and building codes. Installers will connect the unit to the duct system, carefully sealing joints and seams so heated air doesn’t leak into attics, garages, or crawlspaces instead of reaching your rooms.

For gas furnaces, tight, code‑compliant gas line connections and proper venting or flue piping are essential for safe operation and to remove combustion gases from the home. Electric and heat‑pump systems require correctly sized wiring, breakers, and disconnects to handle the load without overheating or nuisance tripping.

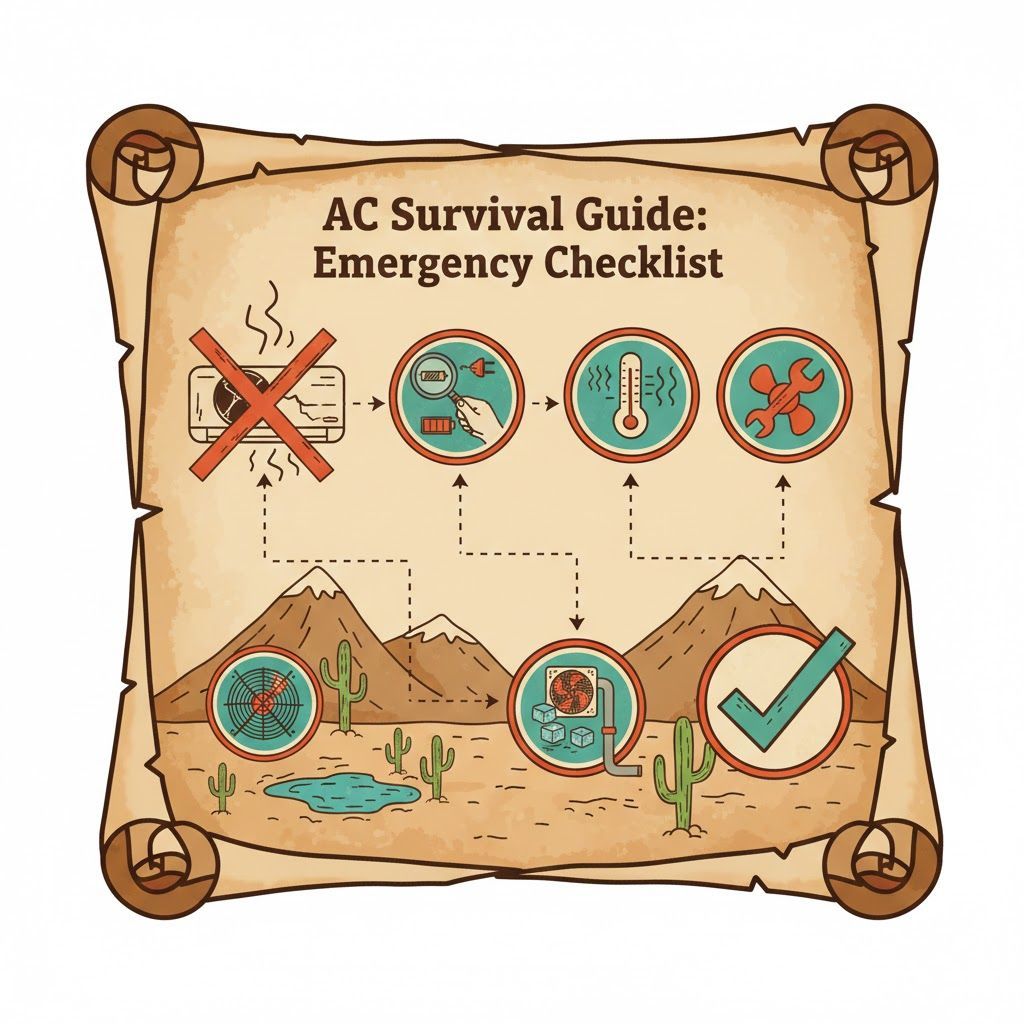

6. Thermostat, airflow, and system testing

Once the heater is in place, your installer should connect and program a compatible thermostat, then run the system through a full startup sequence. This includes checking airflow at supply and return vents, verifying that ducts are not leaking excessively, and ensuring each room is getting adequate warm air.

They will also inspect safety controls, confirm correct gas pressure or electrical readings, and check for error codes or unusual noises during operation. A thorough test run helps catch problems like reversed polarity, incorrect blower speeds, or draft issues before the installer leaves your home.

7. Final safety checks and homeowner education

Before the job is complete, your contractor should perform final safety checks, such as verifying carbon monoxide levels (for fuel‑burning heaters), confirming proper venting, and ensuring all panels and doors are secure. Documentation of permits, inspections, and warranty registration should be provided so you know your installation meets local requirements and manufacturer standards.

They should also walk you through basic operation—filter changes, thermostat settings, what warning signs to watch for, and how often to schedule maintenance—so you can keep your new heater running efficiently and safely for years. With these guidelines followed, your new installation is far more likely to deliver the comfort, efficiency, and peace of mind you were expecting when you decided to upgrade.

Recent Posts